A faldstool is a stool that can be used to lift objects. Youve probably seen one in a movie thats set in Medieval or Renaissance times-its the distinctive portable chair that a nobleman or Bishop sits on, the one with curved legs and arms that looks like it would fold together. It was possible to build a fald stool from scratch, as the oldest faldstools did actually fold up.

This modern version was designed by Rick Hardin, an artisan who sells his wares at Scandinavian-themed craft shows. (You can see his work at Vikingkrafts.com.) Its based on a simple 16th century German faldstool with straight arms and legs, but Ricks version is wider and taller-for modern-day Vikings-and amazingly sturdy.

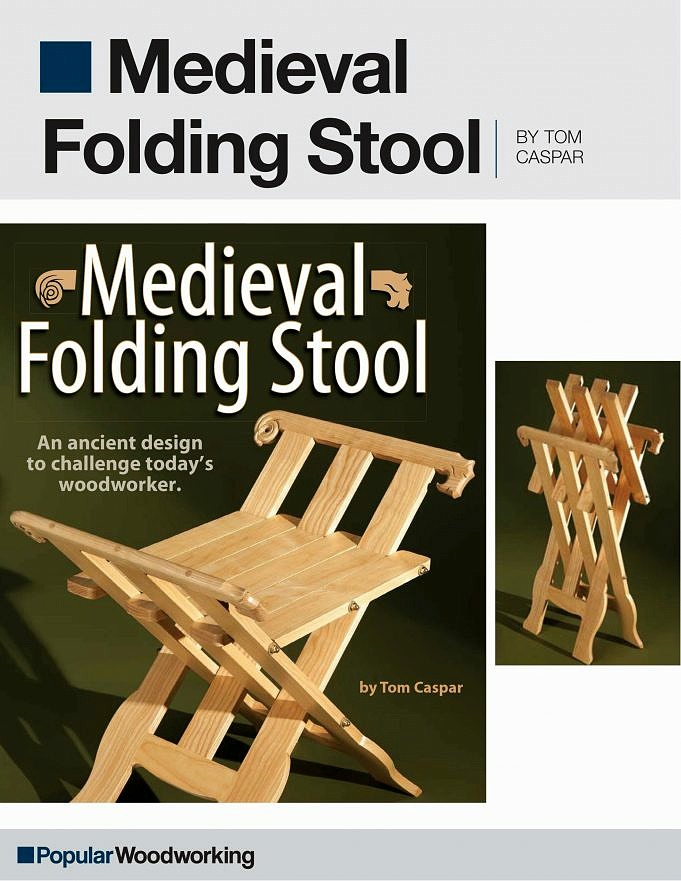

I built the one pictured here from ash, a wood thats central to Norse mythology. Jock Holmen, a local carver who first introduced me to Ricks work, embellished the arms with a Nordic dragon motif. Ricks arms can be simpler. You’ll see them in the drawings as well as how-to photos.

Lifting the seat causes the stool to fold up like an old-fashioned clothes rack. See how its put together below.

Spacers Is The Most Important Component.

The stools are made from 3/10 cm thick pieces. Pre-milled lumber is also an option. If you are using rough lumber, first cut the pieces to oversize in both length and width. Then, joint them and plank them to 3/10cm thick (see Cutting List).

Photo 1. Spacers should be 1/41 cm wider than any parts of the stool. Spacers will allow you to create enough clearance between the parts so that they don’t bind.

Joint one edge of the legs (A) and rip them to final width. Joint this side, too, then trim the legs 1/10 cm extra-long. Joint one edge of the center stiles (B), bottom rails (C) and seat slats (D), then rip them about 1/81 cm extra-wide. Joint the ripped sides, taking a 1/81 cm deep cut to bring the parts to final width. All of these pieces should be trimmed 1/10 cm longer.

Photo 2. The spacers can be used to measure the length of the bottom rail of the stool. The length of the rails equals the widths of two spacers and the widths of the center stile.

Four spacers (F), from 3/10 cm stock. These should be 1/41 cm wider that the seat slats ( Photo 1). Place two spacers alongside a center stile to mark off the exact length of the bottom rails (Photo 2). Reduce the length of the rails.

Photo 3. Rout mortises for loose tenons in the edges of the legs and in the ends of the bottom rails and center stiles. These pieces can be made from the tenons.

I used 1/10 cm loose tenons to join the lower half of the stool, but 3/20 cm dowels or #10 biscuits would work as well. I also used a commercial jig for guiding the router (Photo 3), but of course there are many shop-made devices that could do the trick. Rout 1-3/10 cm wide mortises in the ends of the bottom rails. (Note that the mortises arent centered top to bottom; see Fig. 02). Next, rout mortises of the same size in the ends of the center stiles and in the legs. Finally, place rout mortises on the top rails ( Foto 4). These mortises measure 1-7/20 cm in width.

Photo 4. Rout an extra-wide mortise in the top side of the bottom rail. During glue-up, this mortises extra width will allow you to shift the center stile side-to-side into the correct position, if necessary.

Make 1-3/10 cm wide loose tenon stock (G) and cut it to length. Glue the tenons to the ends of your bottom rails and center stiles. Draw profiles on the bottom rails (Fig. 04), then bandsaw and sand them to final shape.

Cut The Leg Profile

Photo 5. Assemble each half of the stool, without glue, using the spacers. Trim the legs and center stile to final length as a unit, using a crosscut sled.

Next, cut the legs and the center stiles to the final length. The top ends of these pieces have to line up in order to receive the top rail (E). This can be achieved by assembling each side of the stool without glue and cutting all three pieces simultaneously ( Foto 5 ). At least, thats what I thought when I first built the stool. After I glued the pieces together, later on, I found that some had shifted. The tops of the legs and center stile were no longer in alignment. No problem-I just trimmed them as a unit again.

Photo 6. Cut miters on the ends of the legs and seat slats. To position the pieces, use a hinged stopblock. Before you make each cut, open the hinged end to prevent the offcuts from getting trapped, which could cause kickback.

Trim the seat slats to final length. Round the corners of one end of each slat (Fig. 06), then saw 45 angles on the other ends (Photo 6 and Fig. 05). This is where precision is key. The flat end of the angled slats should be exactly 1/20cm wide to ensure that the holes for drilling through the slats are accurately measured. At the same time, saw 45 angles at the bottom of the legs.

Photo 7. Rip the top portion of the legs to final width using a bandsaw, fence and featherboard. Once you reach the curved portion of the legs profile, turn off the saw and back out of the cut.

Now it’s time to finish the legs. Draw profiles on the lower ends of the legs (Fig. 03). then use a bandsaw to rip the upper half of the legs to width, stopping the cut where the profiles curve begins (Photo 7). After repeating the process for all the legs, saw their profiles. Smooth the sawn surfaces; I used a No. I used a No. 80 scraper to smooth the sawn surfaces, but a block plan would also work. However you smooth it, make sure this section stays straight.

Fig. 01. Exploded View

Fig. 02. Leg Assembly

Fig. 03. Leg Pattern

Fig. 04. Bottom Rail Pattern

Fig. 05. Mitered Ends

Fig. 06. Seat Slat Profile

The Cut List

Drill The Rod Holes

In the next steps, youll drill holes for the rods that enable the stool to fold together. While these holes are larger in diameter than the rods, allowing for some play, they must be precisely laid out and drilled to prevent the stools parts from binding. Precision is also necessary to ensure that the seat slats lie in the same plane when the stool is opened, forming a flat seat. The measurements for the rod holes in seat slats are only valid if the material is at least 3/10 cm thick. If its thinner, the holes must be slightly closer together; if thicker, farther apart.

Photo 8. Drill holes for the rods that will pass through the stools folding parts. To ensure the holes are in the right position, use a large support table, stop blocks, a fence and a clamp.

To drill rod holes, the best method is to use a drill press with a fence and a long table ( Photo 8,). The table should support the full length of the workpiece. Clamping the workpiece to the fence ensures that it will be perpendicular when drilled.

You can also use the fence to place a stopblock to make sure all holes are aligned.

Begin by marking the locations of the rod holes through your legs (Fig. 02). Mark centerlines on the legs outside edges, then continue these lines across both faces of the legs. To lay out the corresponding holes in the center stiles, reassemble each half of the chair. Lay a straightedge along the centerlines and continue the lines across the face of each center stile. This method assures that all the holes will be in alignment.

Be sure to center the bit on your stock before you start drilling. A brad point bit is much easier to set up than a regular twist bit. Drill the holes through all the legs and seat slats (Fig. 07), then use a cordless drill and a countersink bit to form large chamfers on both sides of each hole. These chamfers will make the chair much easier to assemble.

Photo 9. Glue the leg assemblies together, again using the spacers to ensure that the legs and center stile remain parallel. Spacers ensure that the openings between legs and stile are equal in width.

Glue the leg assemblies together (Photo 9). Clamp a pair of battens across the top of the legs and center stile to ensure that they stay in the same plane. In addition, place a clamp across the assembly, above the bottom rail, to pull the legs tight against the spacers.

Photo 10. Attach ears to the ends of top rails. You can cut them or carve them however you like to personalize your stool.

The stools top rails (E) are the last wood parts you need to address. They should look like theyre made from one piece, but their lower edges-the part that butts against the legs and center stile-must be absolutely straight. This can be achieved by making the pieces extra wide and then ripping them in half. Joint the lower side of the upper section, then drill holes in it for the screws that will fasten the rails in place. The lower section can be cut into three pieces. After gluing the ends to the upper section, Photo 10, you can cross-cut the lower section. Lay out and saw the rails profile (Fig. 09).

Fig. 07. Rod Hole Locations

Fig. 08. Rod Length

Fig. 09. Top Rail Pattern

Make The Rods And Assemble

sTheres one more set of parts to make: the four metal rods (J) that pass through the stool. There are two types of round rods available in hardware stores: hot-rolled or cold-rolled. Cold-rolled is the best. Hot-rolled rod is covered with a tough scale that can damage a tap, and generally isnt truly round.

Measure the length of the rod by placing one seat slat along with a leg assembly. Measure this distance, then add enough additional length for the rod to bottom out in a pair of cap nuts (K) and pass through a pair of washers (L). You should also allow for two healthy spaces between the washers (Fig. 08).

Photo 11. Thread the ends of four pieces of 1/10 cm cold-rolled rod. Make sure the threads are straight with a tap that you have purchased from a local shop.

Cut the rod to length, then thread about 3/10 cm down both ends of each piece (Photo 11). I made an improved holder for my 1/4-20 tap to ensure that the threads would be straight.

Photo 12. Assembling the stool is a four-step process. First, insert a rod through both leg assemblies.

Photo 13. Attach the top rails to both assembly with screws. Clamp the parts together to make sure they stay flush.

Assemble your stool so that the rod holes line up. First, run one rod through the lower holes in both leg assemblies (Photo 12). Next, attach both top rails ( Photo 13). You can make the plugs (H) that cover the screws at this time, but dont glue them in the holes yet. Third, install both sets of seat slats using two more rods (Photo 14). Run the last rod between all of the slats (Photo 15). Everything should be in its place when you turn the stool upside down.

Photo 14. Next, install seat slats on both sides of the stool. The slats also pivot on a rod.

Photo 15. Complete the assembly by passing a rod through the center of all of the slats. To hold the rods in place, attach thread cap nuts to both ends.

With so many interlocking pieces, its best to finish the stool by taking it apart. Temporarily re-attach the top rails, break every sharp edge with 100-grit sandpaper and apply three coats of finish (I used a water-based poly). Once the stool is reassembled, glue the top rails to the base and attach the screws.

Product Recommendations

These are the tools and supplies we use every day in our shop. Although we may be compensated for sales made through our links, these products have been carefully chosen for their utility and quality.